Read the forum code of contact

By: - 31st July 2008 at 05:13 Permalink - Edited 1st January 1970 at 01:00

.

Here is an interesting graphic showing how the crankshaft remains stationary, while the pistons, the cylinders, and therefore the crankcase all rotate.

The website has further information on interpreting and understanding the graphic.

http://www.keveney.com/gnome.html

regards

Mark Pilkington

By: - 31st July 2008 at 06:26 Permalink - Edited 1st January 1970 at 01:00

Thanks for that graphic Mark. However, it doesn't really show the inner workings of the engine and how it spins. I've been scouring the internet for a detailed graphic, but can't find one. In that graphic, I see that the pistons push the connecting rod, which are connected to the "crankshaft", but that doesn't explain why it rotates around.

By: - 31st July 2008 at 06:43 Permalink - Edited 1st January 1970 at 01:00

bdn12,

Obviously, the power comes from the pistons, but what transfers the pistons motion into rotational motion of the engine block?

In simply terms it is like bolting the crankshaft of a radial so it cant rotate, that causes the crankcase to do so.

I guess strickly speaking, it is after the compression and ignition of the gases within the cylinder, and the expansion of the gases are pushing the piston down, that the angled vector of the con rod at that point pushing on the fixed crankshaft then causes the cylinder to be pushed sideways by the piston on its downward travel thus causing the crankcase to rotate? (as the cylinders are bolted to the crankcase).

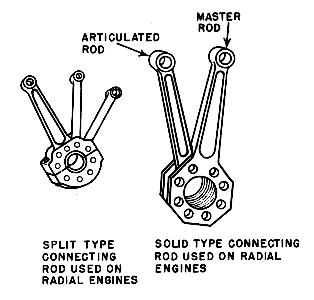

More generally the crankshaft, master and con rods of the Rotary work the same as the Radial, and any other internal combustion engine.

There is a bearing at the crankshaft/master rod connection point, and the master rod rotates, around the crankshaft, which in a rotary is stationary, and which in a radial - rotates.

That point of the crankshaft (the crank pin) is off-set from centre to create the up-down movement of the piston as the engine rotates.

Usually one piston is connected to a master connection rod, with the other pistons connected to that master rod, via individual connection rods, the Master clamps a bearing surface (the big end) around the "crank pin" of the crankshaft, the other "con rods" are then connected to the Master.

http://en.wikipedia.org/wiki/Crankshaft

http://science.howstuffworks.com/radial-engine2.htm

http://www.aviation-history.com/engines/radial.htm

regards

Mark Pilkington

By: - 31st July 2008 at 17:18 Permalink - Edited 1st January 1970 at 01:00

Ah. Ok. Thanks for the explanation. So it basically just uses brute force to turn the whole crankcase around. Thats probably the reason the rpms are much lower on a rotary. In a radial or any other type of engine, only the crankshaft needs to be pushed by the pistons, not the whole engine block.

By: - 31st July 2008 at 18:59 Permalink - Edited 1st January 1970 at 01:00

I was once told that big radials, like the R-2800 ect, have cylinder bores of slightly different sizes. Having scoured the intardnet, I have failed to find references to that anywhere, so any truth to it?

By: - 31st July 2008 at 19:16 Permalink - Edited 1st January 1970 at 01:00

The rotary produces it's own flywheel effect and was a lot smoother than many of it's early contempories.

John

By: - 31st July 2008 at 19:40 Permalink - Edited 1st January 1970 at 01:00

Ah. Ok. Thanks for the explanation. So it basically just uses brute force to turn the whole crankcase around. Thats probably the reason the rpms are much lower on a rotary. In a radial or any other type of engine, only the crankshaft needs to be pushed by the pistons, not the whole engine block.

But, as John Aeroclub has said, it becomes it's own flywheel - I think the lower speed revolving also has to do with it being direct drive ie the propeller rotates at the same speed and doesn't have to be geared down like the majority of piston engines. Lack of gearbox also saves weight.

Another point is the large amount of torque produced by a spinning rotary engine - some pilots found this hard to handle, others made great use of it to turn tightly (but only in one direction!).

Roger Smith.

By: - 31st July 2008 at 20:14 Permalink - Edited 1st January 1970 at 01:00

Hard to handle is a bit of an understatement, I think the term 'Lethal' applies to this type of motor if mishandled, but once mastered the gyroscopic effects of the huge spinning block could be put to good use, it also led too the demise to the type in favour of more conventional designs.

By: - 31st July 2008 at 23:53 Permalink - Edited 1st January 1970 at 01:00

Because most rotaries are aspirated through the crankcase the petrol /air mix tended to wash oil off the bearings hence the use of castor oil as the engine lubricant as it's resistant to petrol. Notice that the first graphic is a Monosoupape with the inlet valve in the piston.

John

By: - 1st August 2008 at 08:50 Permalink - Edited 1st January 1970 at 01:00

More detail

http://thevintageaviator.co.nz/projects/oberursel-engine/rotary-engine-detail

Heres a video of a brand new Oberusel internal workings. it shows how the crank is

offset and further in the vid it shows how the con rods are held onto the stationary crank but slide around enough to work correctly. A lot of metal sliding against metal :)

Paul

By: - 1st August 2008 at 09:46 Permalink - Edited 1st January 1970 at 01:00

The rotary produces it's own flywheel effect and was a lot smoother than many of it's early contempories.

Given that I believe the rear cylinders of the BE2's engine (sorry, exactly what engine that was currently escapes me) were machined with much greater tolerances than the forward ones, because they got so much hotter, I can well believe that the easily-cooled rotary was smoother. The BE2's motor must have piston-slapped like ******y until it got hot!

Adrian

By: - 1st August 2008 at 10:09 Permalink - Edited 1st January 1970 at 01:00

Rotary

BE2's engine (sorry, exactly what engine that was currently escapes me)

RAF1a Also on that website.

Paul

By: - 1st August 2008 at 10:34 Permalink - Edited 1st January 1970 at 01:00

RAF1a Also on that website.

That told me for not looking, didn't it? :o

Adrian

By: - 1st August 2008 at 11:45 Permalink - Edited 1st January 1970 at 01:00

I took me some while to get my head around the workings of a rotary engine.

What I still have trouble with is the Siemens-Halse SH 111 engine that made nearly 200hp in 1917, which was an 11 cylinder geared rotary with cotra-rotating cylinders and crank shaft. Must have been like a swiss clock inside.

Good bit of information on rotaries on this web site and details of the Siemens engine. The bike with a rotary looks fun. http://books.google.co.uk/books?id=gRzsTSKAlDAC&pg=PA18&lpg=PA18&dq=siemens-halske+sh+111&source=web&ots=doU7N9g4zt&sig=RwKrYB6UizfRXje5RI6pUka1hi8&hl=en&sa=X&oi=book_result&resnum=5&ct=result#PPA9,M1

Richard

By: - 1st August 2008 at 12:02 Permalink - Edited 1st January 1970 at 01:00

Try Youtube - I recall a series called "Classic Bikes, probably on Channel 4 - for footage of a rotary-engined bike.

Adrian

By: - 1st August 2008 at 14:52 Permalink - Edited 1st January 1970 at 01:00

Gosh - they've set up the ability to make a brand new Rotary engine. That's quite some project. Does anybody know how long it took them to achieve that?

The Rotary engines are fascinating - how long did they last? When did the Radial start to replace them?

Allan

Posts: 86

By: bdn12 - 31st July 2008 at 03:30

How exactly does a rotary engine operate? I understand that the crankshaft doesn't move and the entire engine block including the cylinders rotate around. But, how do they rotate? Obviously, the power comes from the pistons, but what transfers the pistons motion into rotational motion of the engine block?

Thanks